Our stance:

We continuously attach importance to environment protection and the pursuit of ecological civilization, and we are committed to incorporating sustainable development into corporate activities and decision-making. We continuously promote green product design, packaging-reduction projects, and sustainable logistics. We also promote environmental impact control throughout the entire process, from production and operations to retail products to save energy and resources and reduce emissions and waste. We proactively promote green office operations and conduct various employee activities to enhance the environmental awareness of our employees and their families.

Our Action

Waste classification and treatment measures

- Recyclable waste: wastepaper and scrap metal to be centralized at collection points then classified and passed to relevant departments for recycling

- Non-recyclable waste: domestic and engineering waste to be stored in designated trash cans or places for regular collection by relevant departments

- Hazardous waste: to be centralized at collection points and treated by qualified third parties with strict control and supervision of recycling and disposal

Energy-saving measures

- We purchase electrical equipment with energy-saving labels

- We conduct frequent inspection on power lines and equipment, and take immediate steps to reduce unreasonable power consumption and power loss

- We use high-power energy-saving lamps for lighting. Automatic switching provides sufficient lighting, reduces the number of lamps used, adjusts the lighting time, and turns off the lights automatically when not in used. They are inspected by special personnel

- We strictly manage the use of air conditioners and elevators, and open them only when needed

Energy Efficiency-improving Measures

- We scrap old vulcanization equipment with high energy consumption, replacing with low energy consumption equipment

- We optimize the splat-quenching design of some molds to shorten the quenching time by 40% to improve energy efficiency

- We optimize the rapid heating design of some molds to shorten the rapid heating time by 40% to improve energy efficiency

- We introduced automatic footwear-making equipment, including filmless bottoming machines, automatic rotary sand sieving machines, automatic drying machines, automatic secondary mold wedge forming machines, automatic small foaming machines, and automatic hydraulic rubber press machines

- We use automatic paperbox-folding machines

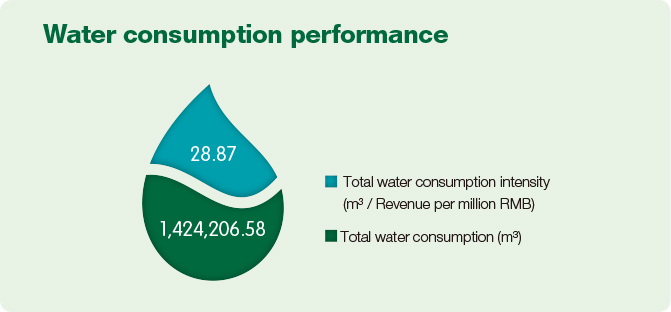

Water Resource-saving Measures

- We renovated the boiler return water piping system to recycle steam boiler water

- We inspect the plumbing equipment daily to prevent water pipes from dripping, leaking and bursting that would result in equipment damage

- We sink filled-up bottles into the flushing water tanks in the factory toilets to take up volume and reduce the amount of flushing water needed

- We use moderate size faucet valves to prevent the waste of water resources

Green Office Measures

- We established a regular inspection system in public areas and conduct safety hazard inspections to ensure low per-capita energy consumption

- We posted guidelines on air conditioners and light switches to remind employees to reduce energy consumption whenever possible

- We regularly maintained our office equipment to extend the service life and improve resource efficiency

- We promoted a paperless office and implemented unified management of office stationery, such as pens, ink and paper

- We replaced some business trips with video conferences to reduce GHG emissions

- We set double-sided printing as the default setting to reduce office paper consumption